Sustainability

Sustainable HR Development

Founded in 1976, Eastern Ever operates five major production bases worldwide with 500 employees working together to create a sustainable future.

- Diversity & Inclusion: Embracing differences in nationality, gender, and belief, encouraging innovation.

- Safety & Health: Implementing international-level safety management with zero major incidents.

- Learning & Development: Cultivating technical and managerial talent while promoting technology exchange across the Asia-Pacific region.

- Social Engagement: From recycling initiatives in Taiwan to local environmental advocacy in Southeast Asia.

" Happy workplaces build competitiveness; sustainable practices secure a better future."

- Eastern Ever Sustainability Committee

Sustainable Production

As a plastics manufacturing company, we rely on resources such as energy, electricity, fossil raw materials, and water, which do not inherently align with sustainable management goals. We recognize that the efficient use of these resources is crucial for the future of our planet and generations to come. We define ‘efficient use’ as extracting maximum value from raw materials. Our aim is to use resources wisely and keep them within a circular material flow. Professional collection and recycling of discarded plastics help prevent environmental pollution and associated hazards.

Energy Management

- We conduct annual energy assessments, identifying an average of 10% potential energy savings.

- We continuously invest in high-efficiency equipment upgrades to reduce costs and carbon emissions.

Renewable Energy

- We have implemented solar power, rainwater harvesting, and wastewater reuse systems in Taiwan, China, Thailand, and Vietnam.

- Year by year, we increase the share of green electricity to support our decarbonization vision.

Material & Resource Management

- We partner with appliance recyclers and research institutions to enhance recycled material efficiency.

- Explore renewable plastic sources, and avoid hazardous substances.

Material & Resource Management

- We partner with appliance recyclers and research institutions to enhance recycled material efficiency.

- Explore renewable plastic sources, and avoid hazardous substances.

Carbon Dioxide (CO2e) Calculation and Certification

- We conduct carbon footprint assessments following the GHG Protocol and continuously promote reduction efforts.

- We provide customized carbon footprint calculations and certification to help customers achieve their ESG goals.

We happy to assist clients in developing sustainable plastic material solutions. We calculate product carbon emissions in accordance with current regulations and provide the corresponding certificates. For personalized guidance, please contact our sales team or the Eastern Ever Sustainability Management Department.

Circular Economy

Our goal is to become the most sustainable PCR manufacturer, committed to achieving the four 'R's:

Reduce

Using less material lowers CO₂e emissions. We optimize ultra-light, high-performance components to minimize material use and significantly reduce the carbon footprint of our product.

Reuse

Like other packaging materials, plastics can also be reused. The longer they maintain their original form within the cycle, the more beneficial they are to the climate. Therefore, we continuously optimize aspects such as the production and performance of plastic pellets, so that they can be integrated into existing reusable systems. At the same time, we are phasing out additives that cannot be reintegrated into the recycling system, such as mica.

Recycling

Plastics are valuable resources, not waste. We keep materials in the recycling loop, transforming them into rHIPS and rABS for new components, reducing resource use and carbon emissions.

Replace

Future Trends in Plastic Materials

Not all plastics are equal. As leaders in recycled materials, we develop resource-saving alternatives, including ocean-bound and used cooking oil-based plastics for the next generation of sustainable materials.

To continuously drive this development, we invest in research and development of recycled plastic solutions that truly address the challenges of today. This reflects our commitment to innovation.

Training & Certifications

Ethical Recruitment & Employment Standard (ERES) Training

CDP Surveys

Through CDP's public environmental disclosure, organizations can comprehensively understand their environmental dependencies, risks, impacts, and opportunities. Leading companies leverage this transparent mechanism to drive action, secure funding, reduce risks, and improve efficiency—going beyond mere regulatory compliance to gain a competitive advantage. Eastern Ever (EE) has proactively participated in, registered for, and completed CDP surveys. This disclosure enables us to make environmentally responsible decisions while supporting business objectives.

Science Based Targets initiative (SBTi)

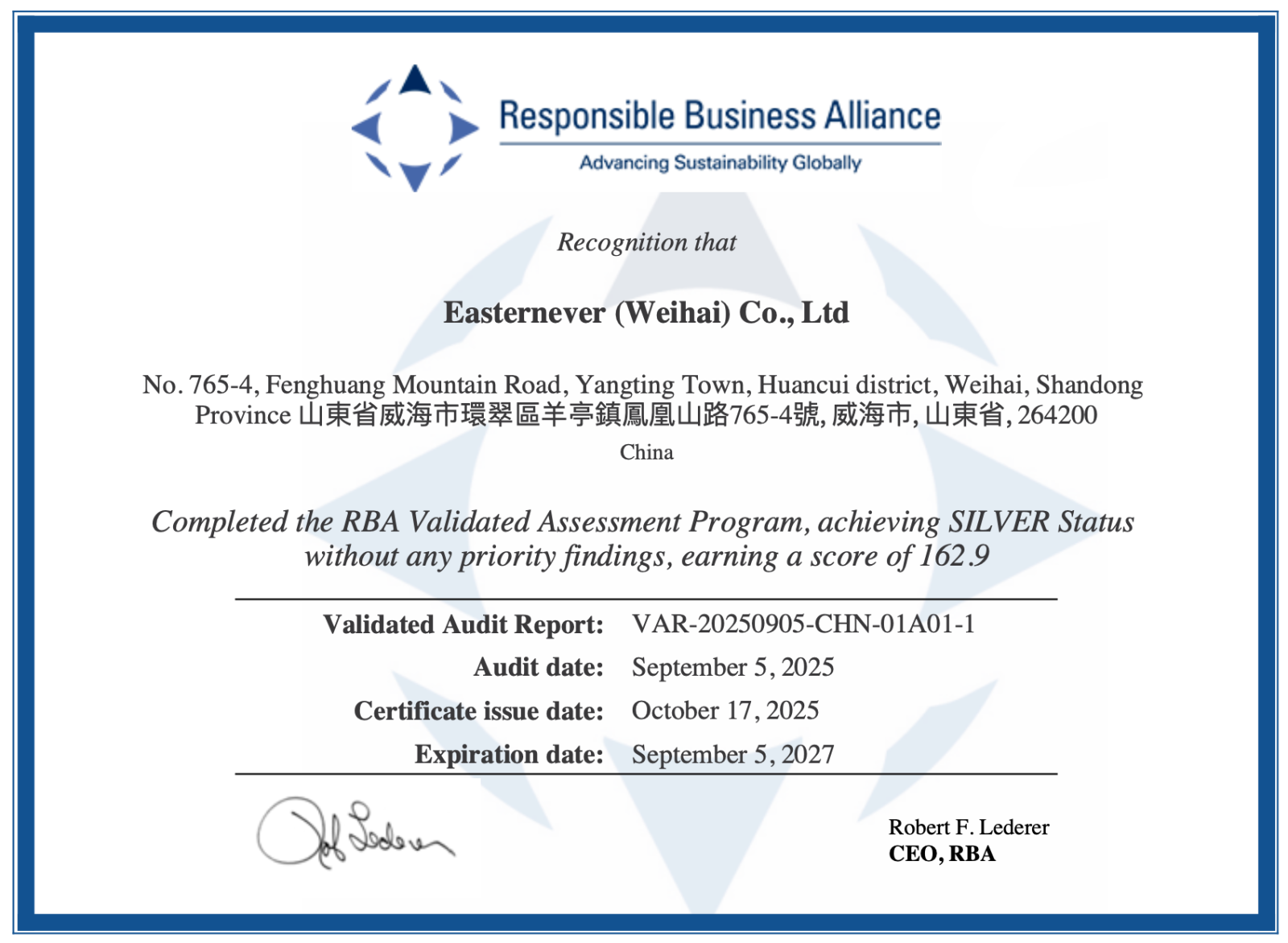

RBA VAP Audit

The Responsible Business Alliance (RBA) Validated Assessment Program (VAP) audit is increasingly important for evaluating supplier operational performance. Eastern Ever (EE) successfully completed the RBA VAP audit in October 2026.